The service life of alloy grinding heads is affected by a variety of factors, mainly including the following aspects.

● Factors of the Grinding Head Itself

Material: Alloy grinding heads of different materials have different properties such as hardness, wear resistance, and toughness. For example, diamond grinding heads have extremely high hardness and good wear resistance, and their service life is usually relatively long. On the other hand, aluminum oxide grinding heads have relatively lower hardness, and they may wear more quickly when processing high-hardness alloys.

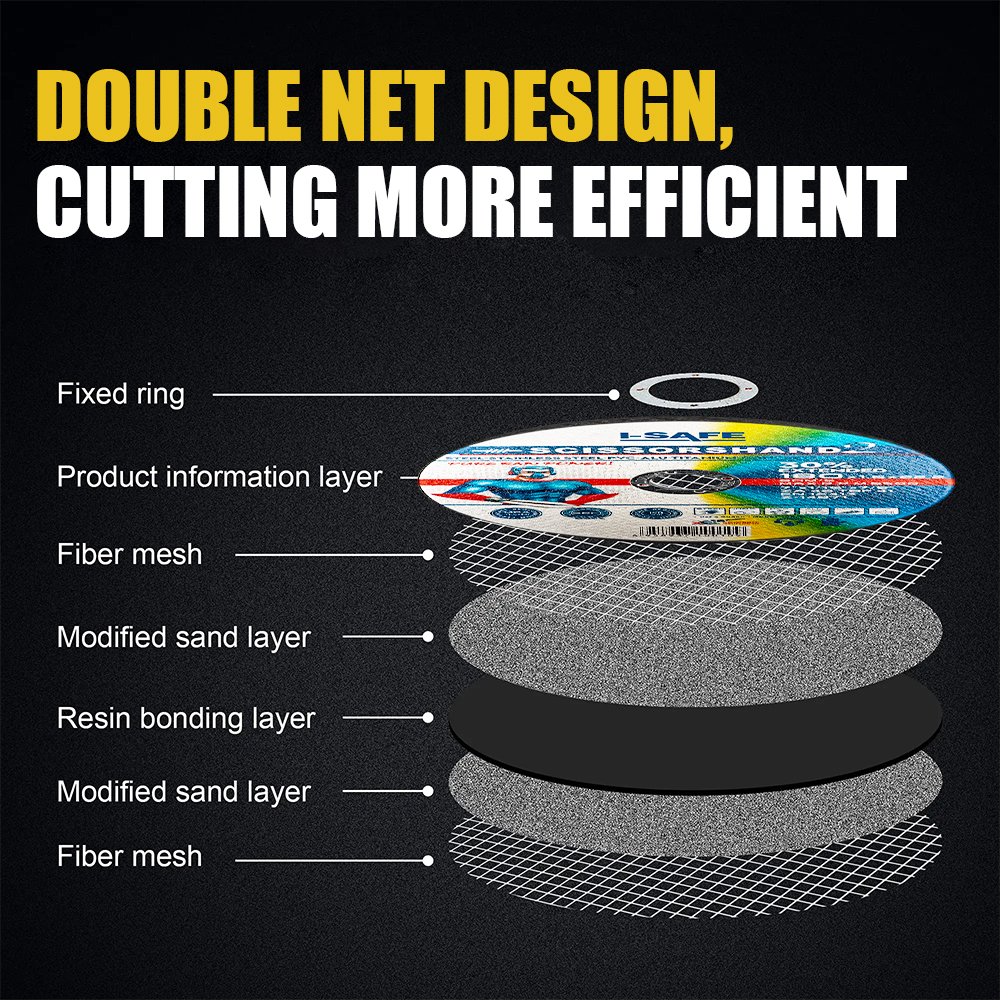

Manufacturing Process: Alloy grinding heads with exquisite manufacturing processes have a dense and uniform internal structure, and the abrasive is firmly bonded to the binder. They can better withstand grinding forces and frictional forces, and are less likely to have problems such as abrasive shedding and deformation of the grinding head, thus prolonging the service life.

● Factors of the Workpiece Material

Hardness: The higher the hardness of the alloy material being processed, the greater the wear on the grinding head. For example, when processing cemented carbide, the wear rate of the grinding head will be much faster than when processing ordinary aluminum alloys.

Toughness: Materials with good toughness will generate greater frictional forces and impact forces on the grinding head during the grinding process, which is likely to cause the abrasives of the grinding head to wear or shed, affecting the service life.

● Factors of Processing Parameters

Grinding Speed: If the grinding speed is too high, the friction between the grinding head and the workpiece material will intensify, generating a large amount of heat, which will accelerate the wear of the grinding head. At the same time, high-speed rotation may also subject the grinding head to a large centrifugal force, making it prone to abrasive shedding or cracking of the grinding head.

Feed Rate: An excessive feed rate will increase the amount of material cut by the grinding head each time, thus increasing the wear degree of the grinding head. If the feed rate is not uniform, it will also lead to severe local wear of the grinding head and shorten the overall service life.

Grinding Pressure: Applying too much grinding pressure will increase the contact stress between the grinding head and the workpiece material, accelerating the wear and shedding of the abrasives. Moreover, excessive pressure may cause the grinding head to deform, affecting the machining accuracy and its own service life.

● Factors of the Processing Environment

Temperature: In a high-temperature environment, the hardness of the alloy grinding head will decrease to some extent, and the wear rate of the abrasives will accelerate. At the same time, high temperatures may also lead to a decline in the performance of the binder, weakening the bonding force between the abrasive and the binder, and making it easy for the abrasives to shed.

Humidity: In a humid environment, alloy grinding heads may rust, especially for some grinding heads made of metal materials. Rusting will reduce the surface hardness and wear resistance of the grinding head, thereby affecting its service life. In addition, a humid environment may also affect the performance of the binder, leading to abrasive shedding.

Dust: If the dust generated during the processing cannot be discharged in a timely manner, it will accumulate on the surface of the grinding head. On the one hand, it will affect the heat dissipation of the grinding head, and on the other hand, the hard particles in the dust may further accelerate the wear of the grinding head.

● Factors of Maintenance

Correct Usage Method: Operators who use alloy grinding heads in accordance with the correct operating procedures, such as avoiding overloading and regularly checking the wear condition of the grinding head, can extend its service life.

Timely Cleaning and Maintenance: Regularly clean the debris and dust on the grinding head to prevent their accumulation from affecting heat dissipation and increasing wear. At the same time, appropriate maintenance of the grinding head, such as applying anti-rust oil and replacing worn parts regularly, also helps to extend its service life.

Proper Storage: Store the alloy grinding head in a dry and well-ventilated environment, and avoid collisions and squeezing to prevent it from deforming or being damaged.