The following is the translation of the characteristics and applications of carbide rotary files, tungsten steel grinding heads, milling cutters, electric drill files, grinding tools, and drill bits.

Carbide Rotary Files Characteristics

Wide range of materials for processing: It can process metals such as cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper, and aluminum, as well as non - metals such as marble, jade, and bone. The processing hardness can reach HRA≥85.

High - efficiency and environmentally - friendly: It can replace the small - handle grinding wheel, without dust pollution. The processing efficiency is dozens of times higher than that of the manual file and nearly ten times higher than that of the small - handle grinding wheel.

Good processing quality: It has a high finish and can process various high - precision mold cavities.

Long service life: The durability is ten times higher than that of high - speed steel tools and more than 200 times higher than that of small grinding wheels.

Easy to use: It is easy to master, simple to use, safe and reliable, and the comprehensive processing cost can be reduced by dozens of times.

Applications: It is widely used in industrial sectors such as machinery, automotive, shipbuilding, chemical industry, and craft carving. It can be used for the finish - machining of metal mold cavities; the removal of flash, burrs, and weld seams of castings, forgings, and weldments; the processing of chamfers, fillets, grooves, and keyways of mechanical parts; the polishing of impeller flow channels; the cleaning of pipes; the finish - machining of the inner hole surfaces of mechanical parts; and the craft carving of various metals and non - metals.

Tungsten Steel Grinding Heads Characteristics

High hardness: It can process various metals and non - metals, and the processing hardness can reach up to HRC70.

Good quality and high finish: It can process various high - precision mold cavities.

High - efficiency and environmentally - friendly: In most work, it can replace the small - handle grinding wheel, without dust pollution. Its use is equivalent to several hundred small - handle grinding wheels, the processing efficiency is increased by more than 5 times, and it is dozens of times higher than the processing efficiency of files.

Applications: Similar to carbide rotary files, it is often used on pneumatic or electric - driven tools for grinding, trimming, and polishing various materials, such as in the fields of mold manufacturing, mechanical processing, and handicraft carving.

Milling Cutters Characteristics

High cutting efficiency: Through rotary cutting, materials can be quickly removed, and the processing efficiency is high.

High processing accuracy: It can process various surfaces with different shapes and accuracy requirements, such as planes, curved surfaces, and grooves.

Many types of tools: According to different processing requirements, there are various types and specifications to choose from, such as end - milling cutters, vertical milling cutters, and ball - end milling cutters.

Strong adaptability: It can be used to process various materials, including metals and non - metals.

Applications: It is widely used in the mechanical processing field, such as mold manufacturing, aerospace, and automotive manufacturing. It is used for processing the planes, sides, steps, grooves, and cavities of parts, and can also be used for carving and milling complex curved surfaces.

Electric Drill Files Characteristics

Good portability: It can be installed on an electric drill for use, which is convenient to carry and operate, and is suitable for processing in various occasions.

High filing efficiency: With the help of the rotary power of the electric drill, the filing efficiency is higher than that of the manual file.

Flexible replacement: There are various shapes and sizes of files available, which can be replaced according to different processing requirements.

Applications: It is mainly used for filing metals, wood, plastics, and other materials, such as trimming the edges of parts, removing burrs, and processing grooves. It has certain applications in mechanical maintenance, handicrafts, and woodworking.

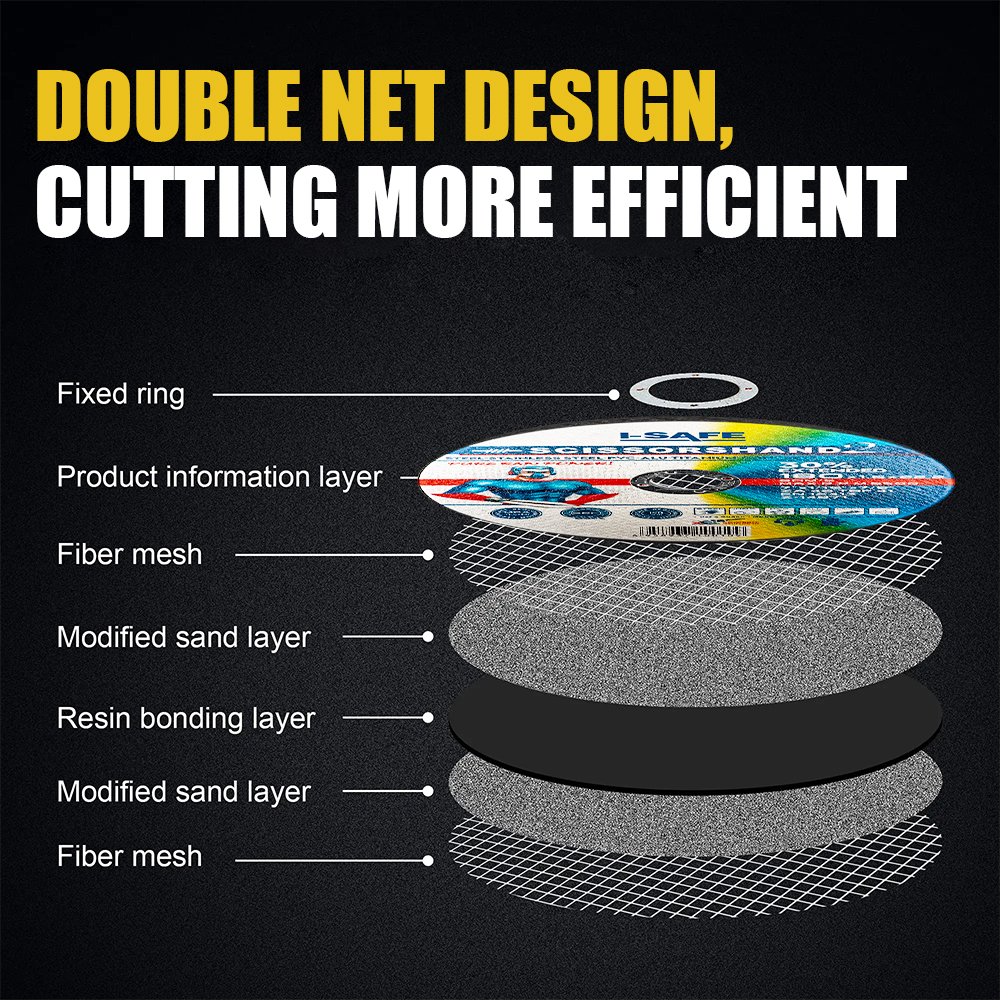

Grinding Tools Characteristics

Diverse types: Including sandpaper, sand belts, grinders, polishing pastes, etc., and the appropriate tools can be selected according to different processing requirements.

Improve surface quality: Through grinding and polishing, the workpiece surface can reach a high finish and accuracy, improving the surface quality.

Flexible operation: It can be operated manually or with the assistance of mechanical tools, and is suitable for workpieces of various shapes and sizes.

Applications: It is used for the surface treatment of various materials, such as the polishing of metal parts, the grinding of wood, and the surface trimming of plastic parts, to improve the appearance quality of the workpiece, reduce the surface roughness, and remove the oxide scale.

Drill Bits Characteristics

Suitable for drilling in complex materials: It can choose a relatively high cutting speed and can drill holes in a variety of materials.

Good wear resistance: High - performance alloy blades specially selected for alloy drill bits can effectively reduce tool breakage and maintain good wear resistance.

Good chip - removal performance: Multi - layer geometric cutting end blades improve the chip - removal performance and maintain a small cutting resistance.

Diverse shank types: In addition to the commonly used right - angle shank, there are various shank types available, which are suitable for use with a variety of drilling machines and drill presses.

Applications: It is widely used in the construction, mechanical processing, and decoration fields, and is used to drill holes of different diameters and depths in various materials. For example, it is used to drill holes in metal plates for installing bolts and in walls for installing expansion screws.