The size specifications of abrasive flap discs have several implications for industrial applications, mainly influencing aspects such as grinding efficiency, surface finish, equipment compatibility, and material consumption.

Grinding Efficiency

Larger Diameter:

Larger - diameter abrasive flap discs have a larger contact area with the workpiece, allowing more abrasive particles to act on the surface simultaneously. This enables them to remove material at a faster rate, thereby increasing grinding efficiency. For example, in the steel - processing industry, when large - scale steel plates need to have their surfaces leveled or have rust and burrs removed, using abrasive flap discs with a diameter of 200mm or more can significantly reduce the processing time.

Smaller Diameter:

Small - diameter abrasive flap discs have a smaller contact area and are suitable for grinding in narrow spaces or areas with complex shapes. Although their material - removal rate per unit time is relatively low, they can be used in conjunction with specialized small - angle grinders, which are very useful for detailed work such as internal - hole grinding and corner grinding.

Surface Finish

Larger Diameter:

During the grinding process, larger - diameter abrasive flap discs rotate more stably, and the abrasive particles on their edges move more smoothly. This helps to reduce surface scratches and roughness, resulting in a better - quality surface finish. In the automotive - manufacturing industry, when grinding and polishing the surfaces of car body parts, large - diameter abrasive flap discs are often used to achieve a smooth and shiny surface.

Smaller Diameter:

Small - diameter abrasive flap discs are more flexible and can better conform to the contours of the workpiece surface. This makes them suitable for fine - tuning and polishing operations, which can improve the surface finish in specific areas and are suitable for processing parts with high - precision surface requirements, such as aerospace - component manufacturing.

Equipment Compatibility

Diameter Compatibility:

The diameter of the abrasive flap disc must be compatible with the grinding equipment. Different grinders are designed to accommodate specific ranges of disc diameters. Using an overly large or small disc can lead to inefficient operation, reduced equipment lifespan, and potential safety hazards. For instance, bench - grinders usually work best with abrasive flap discs within a certain diameter range. If a disc that is too large is installed, it may exceed the grinder's power - handling capacity and cause the motor to overheat or even malfunction.

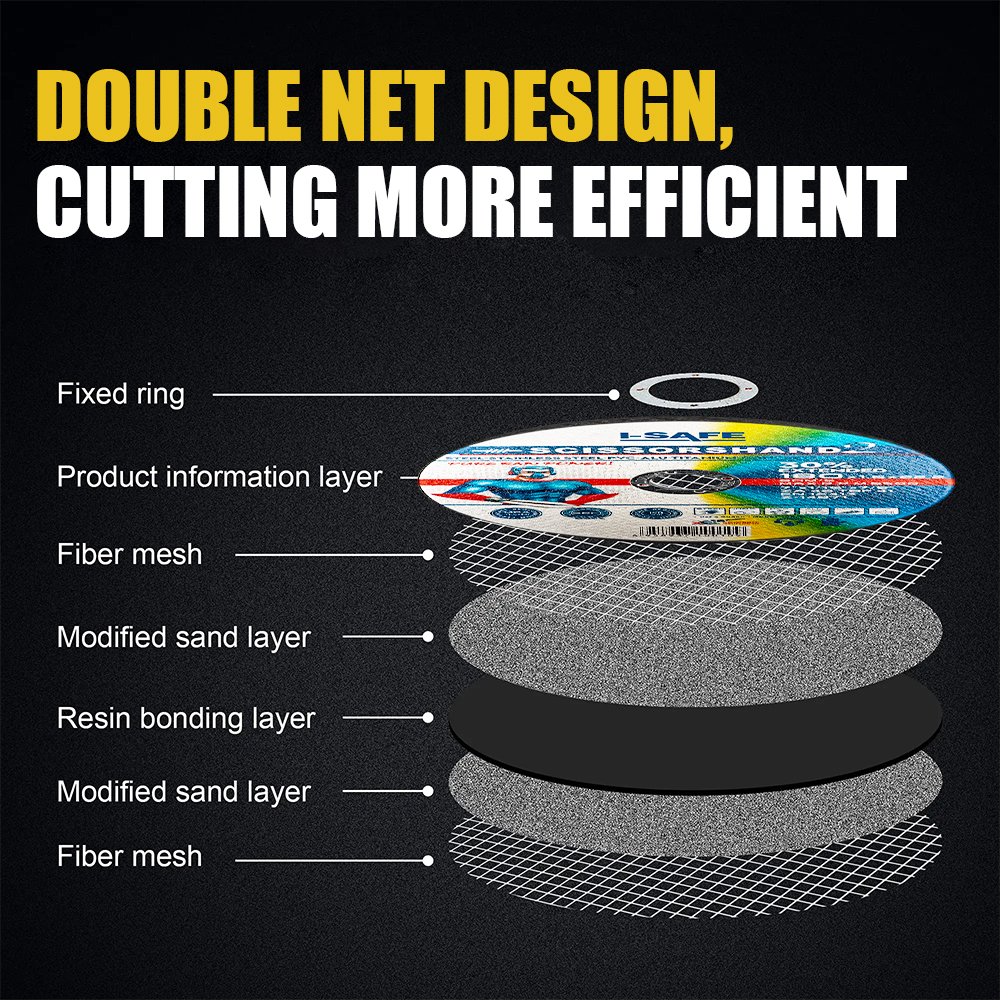

Thickness Considerations:

The thickness of the abrasive flap disc also affects its compatibility with the equipment. Thicker discs may require more space between the grinder's spindle and the workpiece, and they may also impact the balance and stability of the grinding process. In some cases, special adapters or modifications to the equipment may be necessary to use thicker - than - standard abrasive flap discs.

Material Consumption and Cost

Larger Diameter:

Larger - diameter abrasive flap discs generally consume more abrasive material. Since they have a larger surface area and more abrasive particles, they wear out faster under the same grinding conditions. This means that they need to be replaced more frequently, increasing the overall cost of abrasive materials. However, in some high - volume production scenarios, the increased efficiency of using large - diameter discs can offset the higher material cost to a certain extent.

Smaller Diameter:

Small - diameter abrasive flap discs consume less material, but they may require more time and a larger number of discs to complete the same amount of work. This is because their material - removal rate per unit time is lower. Therefore, when choosing the size of the abrasive flap disc, it is necessary to comprehensively consider the specific processing requirements, production volume, and cost factors to achieve the best balance between efficiency and cost.