Selecting the appropriate alloy grinding head requires a comprehensive consideration of multiple factors such as the processing material, technological requirements, and equipment conditions. The following are some key considerations:

● Processing Material

Material Hardness: For materials with high hardness, such as cemented carbide and quenched steel, a grinding head with higher hardness and better wear resistance should be selected, such as a diamond or cubic boron nitride (CBN) grinding head. For materials with lower hardness, such as aluminum alloys and copper alloys, aluminum oxide or silicon carbide grinding heads can be used, which have good cutting performance and cost-effectiveness.

Material Toughness: Materials with high toughness are likely to cause the abrasives of the grinding head to wear or fall off. When processing such materials, it is advisable to choose a grinding head with good toughness and self-sharpening properties. For example, a diamond grinding head with a rubber binder is suitable for processing stainless steel and other materials with high toughness. Its elasticity can buffer the grinding force and reduce the shedding of abrasives.

● Technological Requirements

Machining Accuracy: If a high machining accuracy is required, a grinding head with good shape retention and high dimensional accuracy should be selected. For example, in precision mold processing, high-precision diamond electroplated grinding heads are often used, which can ensure stable dimensions and shapes during long-term processing, thus achieving high-precision grinding.

Surface Quality: For processing that requires a low surface roughness, a grinding head with fine particle size and uniform grinding force should be selected. For instance, in the grinding of optical lenses, a diamond grinding head with a resin binder is used. Its delicate grinding effect can make the lens surface reach a high level of finish.

Processing Efficiency: In occasions where high processing efficiency is required, such as in mass production, a grinding head with high grinding efficiency should be selected. For example, CBN grinding heads have high cutting efficiency and can remove a large amount of material in a short time, making them suitable for high-efficiency grinding of steel materials.

● Equipment Conditions

Machine Tool Type: Different types of machine tools have different adaptabilities to grinding heads. For example, high-speed grinders require grinding heads with good dynamic balance performance and the ability to adapt to high rotational speeds to avoid vibrations during high-speed rotation, which may affect the processing quality and the service life of the equipment.

Power Size: When the power of the machine tool is relatively large, a larger-sized grinding head with stronger grinding force can be selected to fully utilize the power advantage of the machine tool and improve processing efficiency. For machine tools with relatively low power, lightweight grinding heads with moderate cutting force should be selected to prevent the machine tool from being overloaded.

● Cost Factors

Initial Cost: The prices of different types of alloy grinding heads vary greatly. Diamond and CBN grinding heads are relatively expensive due to the particularity of their materials and manufacturing processes, while aluminum oxide and silicon carbide grinding heads are more affordable. If cost sensitivity is high and the processing requirements can be met, priority can be given to grinding heads with high cost-effectiveness.

Service Life: Although some high-cost grinding heads have a relatively high initial price, if they have a long service life and high grinding efficiency, they may actually reduce the overall cost in the long run. For example, although diamond grinding heads are expensive per unit, when processing high-hardness materials, their good wear resistance leads to a low replacement frequency, and the comprehensive cost may have more advantages.

● Other Factors

Grinding Head Shape: Select a grinding head of an appropriate shape, such as cylindrical, conical, spherical, etc., according to the shape and size of the processed part. For example, when processing an inner hole, a cylindrical or ball-nosed grinding head is required; when processing the cavity of a mold, various special-shaped grinding heads may be needed to adapt to complex curved surfaces.

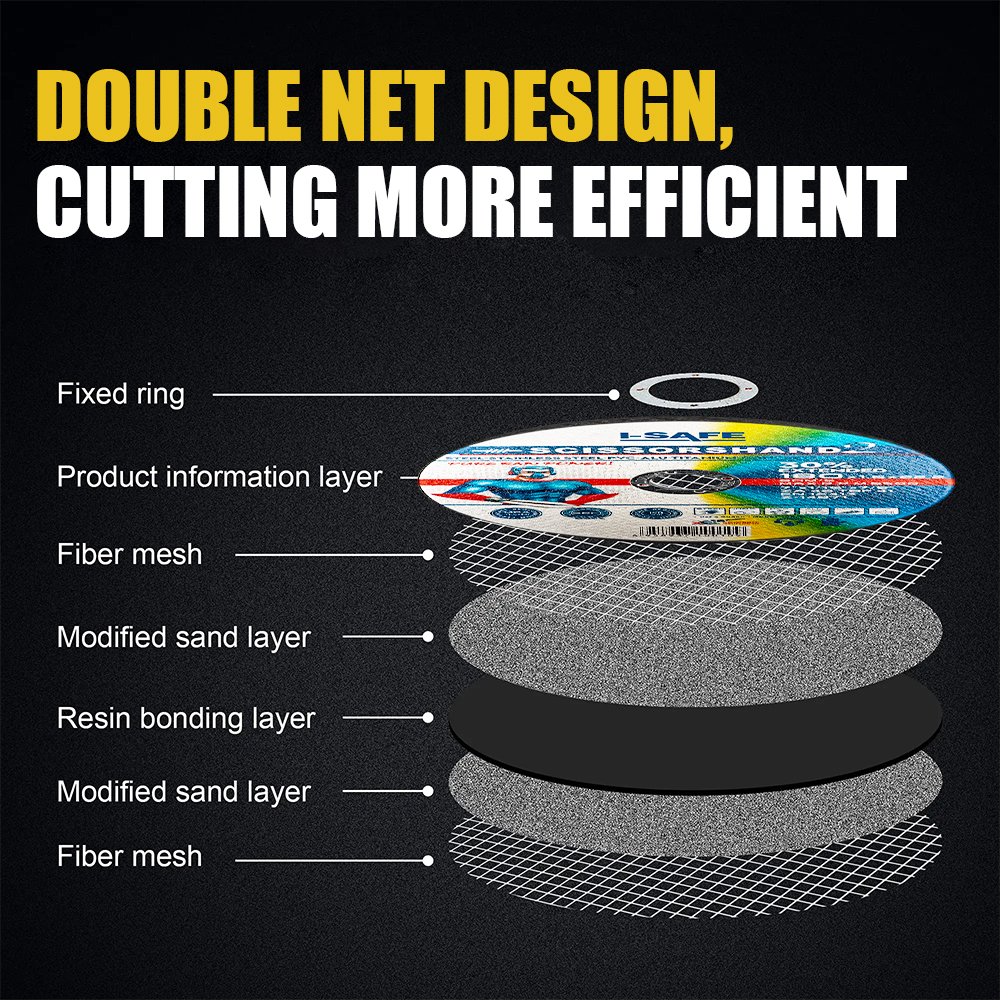

Binder Type: Common binders include resin, metal, ceramic, etc. Grinding heads with a resin binder have good elasticity and self-sharpening properties and are suitable for fine grinding and polishing.