The following are the advantages and disadvantages of different types of abrasive flap discs in industrial applications.

Classification by Abrasive Material

Aluminum Oxide Abrasive Flap Discs

Advantages: Good toughness and a wide range of applications. They can be used for the grinding of various metal materials, such as steel and aluminum alloy, and can effectively remove burrs, oxide scales, and rust on the material surface. Relatively inexpensive, offering high cost-effectiveness.

Disadvantages:

The grinding efficiency is relatively low for high-hardness materials. When grinding materials with high hardness such as alloys or ceramics, they wear out relatively quickly.

Silicon Carbide Abrasive Flap Discs

Advantages: High hardness and strong grinding force, especially suitable for processing hard materials such as cemented carbide and ceramics. At the same time, when finely grinding metal materials, a good surface finish can be obtained.

Disadvantages:

Compared with aluminum oxide abrasive flap discs, they have poorer toughness and are more likely to break. During the grinding process, if subjected to a large impact, the abrasive particles are likely to fall off, affecting the grinding effect and service life.

Zirconia Abrasive Flap Discs

Advantages:

Good wear resistance and heat resistance, often used for high-speed grinding and heavy-duty grinding. They perform excellently when processing difficult-to-machine materials such as stainless steel and nickel-based alloys, can withstand high grinding pressure and temperature, and are not prone to clogging and wear.

Disadvantages: High cost, relatively expensive in price. Due to their special properties, their application range is relatively narrow. For the grinding of some common metal materials, they may not be the option with the highest cost-performance ratio.

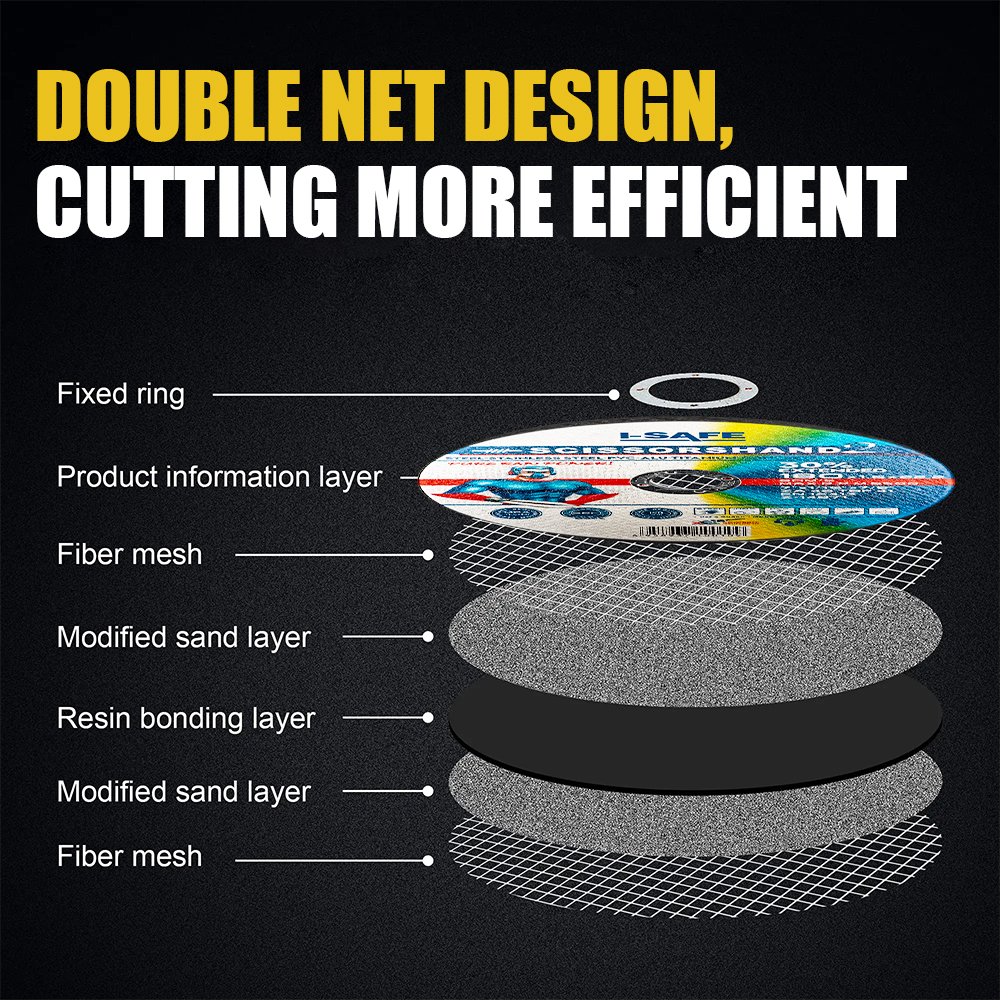

Classification by Binder

Resin Bonded Abrasive Flap Discs

Advantages: Good flexibility and wear resistance, which can firmly bond the abrasive to the base body. During the grinding process, they can adjust automatically according to the shape of the workpiece surface, suitable for the grinding of workpieces of various shapes, especially providing a good grinding effect on curved and irregular surfaces.

Disadvantages:

Relatively poor heat resistance. In the case of high-speed grinding or prolonged grinding that generates high temperatures, the resin binder may soften or char, affecting the service life and grinding quality of the abrasive flap discs.

Ceramic Bonded Abrasive Flap Discs

Advantages:

High temperature resistance and high hardness, able to withstand relatively large grinding pressure, suitable for high-speed grinding and dry grinding. They can still maintain good stability and grinding performance under high temperature and high pressure, with high grinding efficiency.

Disadvantages:

Brittle, and compared with resin bonded abrasive flap discs, they have poorer flexibility. When grinding some workpieces with complex shapes or those prone to deformation, their adaptability is not as good as that of resin bonded abrasive flap discs.

Rubber Bonded Abrasive Flap Discs

Advantages:

Good elasticity. When used in polishing processes with high requirements for surface roughness, they can give the workpiece surface a smooth texture. Less heat is generated during the grinding process, and it is not easy to burn the surface of the workpiece, suitable for processing temperature-sensitive materials such as non-ferrous metals and plastics.

Disadvantages: Relatively weak grinding force, not suitable for removing a large amount of material or grinding materials with high hardness. The wear resistance of the rubber binder is limited, and during long-term or high-intensity grinding operations, the abrasive flap discs may wear out relatively quickly.

Classification by Base Material

Paper-based Abrasive Flap Discs

Advantages:

Low cost, soft texture, suitable for light-load grinding and polishing. They have a good surface treatment effect on soft materials such as wood and plastic, and can also be used for the preliminary processes of fine grinding and polishing of metal materials.

Disadvantages: Low strength, unable to withstand large grinding forces, and are prone to damage during the grinding process. Poor durability, with a relatively short service life, not suitable for high-intensity and long-term grinding operations.

Fiber-based Abrasive Flap Discs

Advantages: High strength and good toughness, able to withstand large grinding forces, suitable for the grinding and polishing of metal materials in various industrial applications. Different thicknesses and densities of fiber bases can be selected according to different grinding requirements, with strong adaptability.

Disadvantages: Higher cost compared to paper-based abrasive flap discs. In some occasions with extremely high requirements for grinding precision, the performance of the fiber base may need to be further optimized to meet higher precision requirements.

Metal-based Abrasive Flap Discs

Advantages: Strong rigidity and good heat dissipation performance, suitable for high-speed grinding and heavy-duty grinding. They can ensure the stability and precision of the base body during the grinding process, especially suitable for processing hard and brittle materials such as cemented carbide and ceramics, as well as for the occasions of high-efficiency grinding of metal materials.

Disadvantages: Relatively heavy weight, which may increase the difficulty of operation when used on some handheld or grinding equipment with high requirements for flexibility. Metal-based abrasive flap discs are relatively expensive in price and have a greater processing difficulty.