When selecting abrasive flap discs suitable for specific industrial applications, the following key factors need to be considered.

1. Abrasive Material

Aluminum Oxide: It has good toughness and a wide range of applications. It can be used for grinding various metal materials, such as steel, aluminum alloy, etc., and can effectively remove burrs, oxide scales, and rust on the material surface.

Silicon Carbide: With high hardness and strong grinding force, it is suitable for processing materials with high hardness, such as cemented carbide and ceramics. It is also suitable for fine grinding of metal materials with high requirements for surface finish.

Zirconium Oxide: It has good wear resistance and heat resistance, and is often used for high-speed grinding and heavy-duty grinding. It is particularly suitable for processing difficult-to-machine materials such as stainless steel and nickel-based alloys.

2. Grain Size

Coarse Grain Size: Such as 36 mesh - 60 mesh, it can remove materials quickly. It is suitable for quickly grinding metal materials, removing a large amount of surplus material or when the surface has severe rust or thick oxide scales. It is often used in the rough grinding process of metal processing.

Medium Grain Size: 80 mesh - 120 mesh, it has a relatively balanced grinding efficiency and surface quality. It can be used for the intermediate grinding process of most industrial applications, preparing for subsequent fine grinding. It can ensure a certain grinding efficiency while making the surface of the workpiece reach a certain finish.

Fine Grain Size: 150 mesh - 240 mesh, it is mainly used for fine grinding and polishing processes. It can make the surface of the workpiece obtain a high finish and precision, and is suitable for occasions with strict requirements for surface quality, such as the processing of optical instrument parts and precision molds.

Ultra-fine Grain Size: 320 mesh and above, it is used for extremely fine polishing treatment, which can make the surface of the workpiece reach a mirror effect. It is often used in high-end jewelry, precision electronic components and other fields with extremely high requirements for surface finish.

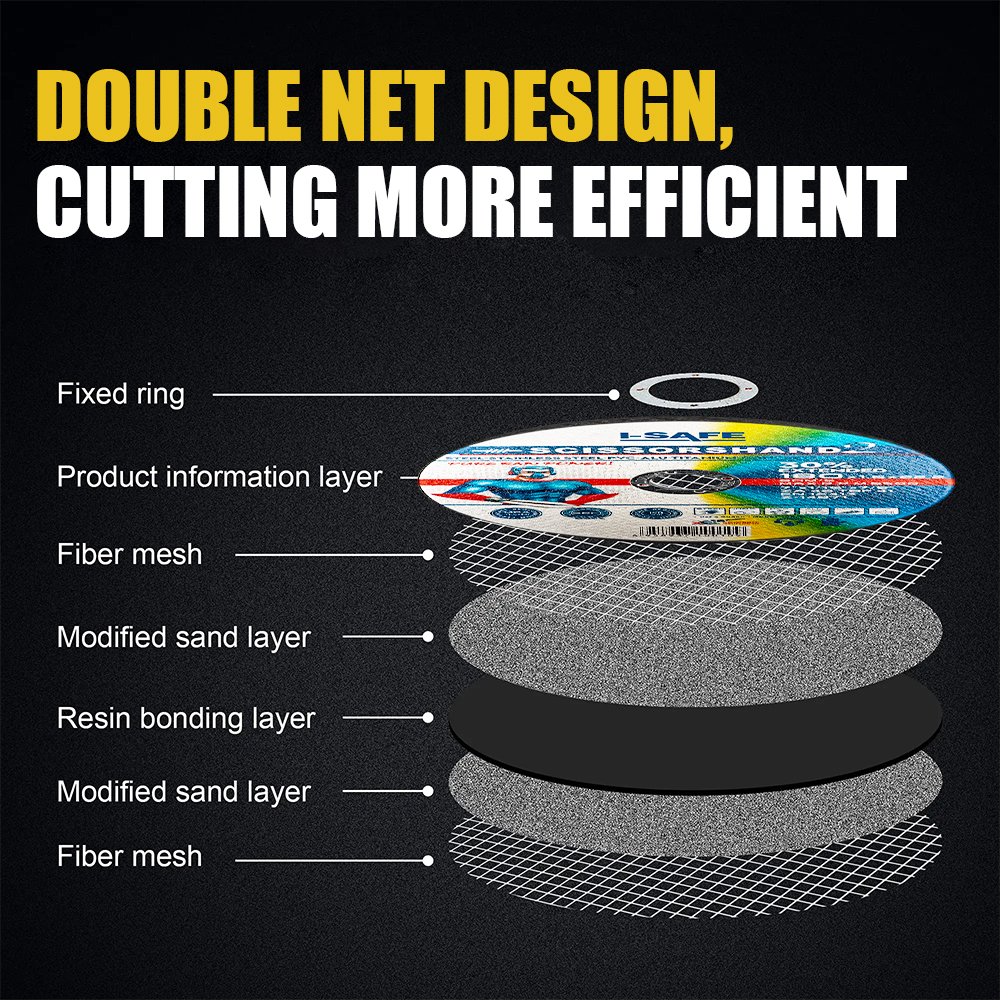

3. Binder

Resin Binder: It has good flexibility and wear resistance, which can firmly bond the abrasive to the base body. At the same time, it can automatically adjust according to the shape of the workpiece surface during the grinding process. It is suitable for grinding workpieces of various shapes and materials, especially performing well in the grinding of curved and irregular surfaces.

Ceramic Binder: It has high temperature resistance and high hardness, and can withstand relatively large grinding pressure. It is suitable for high-speed grinding and dry grinding, and can ensure the stability and grinding performance of the abrasive under high temperature and high pressure. It is often used for the efficient grinding of metal materials.

Rubber Binder: It has good elasticity and can be used for polishing processes with high requirements for surface roughness. It can make the surface of the workpiece obtain a smooth texture. At the same time, less heat is generated during the grinding process, and it is not easy to burn the surface of the workpiece. It is suitable for processing temperature-sensitive materials, such as non-ferrous metals and plastics.

4. Base Material

Paper-based Base: It has a low cost and soft texture, and is suitable for light-load grinding and polishing. It is often used for the surface treatment of soft materials such as wood and plastics, as well as the preliminary process of fine grinding and polishing of metal materials.

Fiber-based Base: It has high strength and good toughness, and can withstand relatively large grinding force. It is suitable for various industrial applications, especially for the grinding and polishing of metal materials. Different thicknesses and densities of fiber-based bases can be selected according to different grinding requirements.

Metal-based Base: It has strong rigidity and good heat dissipation performance, and is suitable for high-speed grinding and heavy-duty grinding. It can ensure the stability and precision of the base during the grinding process. It is often used for the processing of hard and brittle materials such as cemented carbide and ceramics, as well as for the occasions where high-efficiency grinding of metal materials is required.

5. Shape and Size of Abrasive Flap Discs

Shape: Common shapes include circular, square, triangular, etc. Circular abrasive flap discs are suitable for various rotary grinding equipment, such as angle grinders and grinders, and have the widest range of applications; square and triangular abrasive flap discs are more suitable for grinding some workpieces with special shapes or corners and edges.

Size: It should be selected according to the specifications of the grinding equipment and the size of the workpiece. Generally speaking, large equipment and large workpieces are suitable for using abrasive flap discs with a larger diameter and thicker thickness to improve the grinding efficiency; small equipment and small workpieces should use abrasive flap discs with a smaller diameter and thinner thickness to facilitate operation and control the grinding precision.

6. Equipment and Process Requirements

Grinding Equipment: Different grinding equipment has different adaptabilities to abrasive flap discs. For example, angle grinders are suitable for using abrasive flap discs with a smaller diameter and thinner thickness to ensure the flexibility of operation; while grinders can use abrasive flap discs with a larger diameter and thicker thickness to give full play to their grinding ability. In addition, parameters such as the rotation speed and power of the equipment also need to be considered, and abrasive flap discs that match them should be selected to ensure the grinding effect and the safe operation of the equipment.

Grinding Process: The requirements for abrasive flap discs are also different for dry grinding and wet grinding. For dry grinding, abrasive flap discs need to have good heat dissipation performance and chip removal performance to prevent the blockage of abrasives and overheating of the workpiece surface; for wet grinding, abrasive flap discs are required to have good water resistance and rust resistance. At the same time, appropriate abrasives and binders should be selected to ensure that good grinding performance can still be maintained under the action of water-based grinding fluids.

In addition, it is also necessary to refer to the usage evaluations and experiences of other users, and choose brands and suppliers with reliable quality and good reputation to ensure the stable performance and quality of abrasive flap discs.