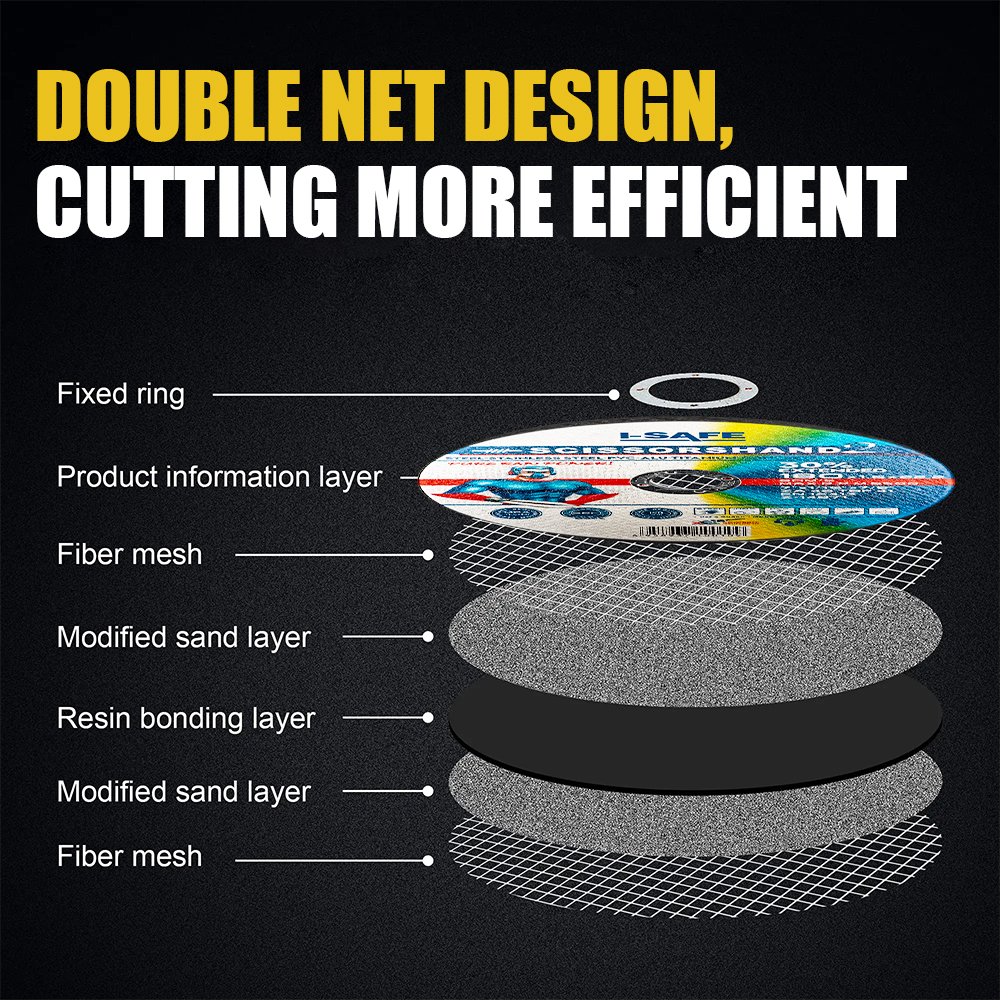

Industrial abrasive flap discs are tools used in processes such as grinding and polishing, typically composed of a base body and abrasive materials. The following are some common types and characteristics of industrial abrasive flap discs.

Classification by Abrasive Material

Silicon Carbide Abrasive Flap Discs

Characteristics: Silicon carbide has a high hardness, excellent wear resistance, and cutting performance. It is suitable for grinding materials with high hardness, such as alloy steel, stainless steel, etc. Silicon carbide abrasive flap discs have high grinding efficiency, which can quickly remove burrs, oxide scales, and other impurities on the surface of the workpiece. At the same time, it can ensure the flatness and smoothness of the workpiece surface.

Applications: Widely used in industries such as machining, automotive manufacturing, and shipbuilding.

Aluminum Oxide Abrasive Flap Discs

Characteristics: Aluminum oxide has high hardness and toughness, and can maintain good shape and cutting performance during grinding. It is suitable for grinding various metal materials, including carbon steel, alloy steel, copper alloy, etc. Aluminum oxide abrasive flap discs have a good grinding effect, which can make the surface of the workpiece reach a high degree of smoothness. At the same time, it can reduce the burn and deformation of the workpiece surface.

Applications: Commonly used in metal processing, mold manufacturing, electronic equipment manufacturing, and other fields.

Diamond Abrasive Flap Discs

Characteristics: Diamond is the hardest substance in nature, so diamond abrasive flap discs have extremely high wear resistance and cutting ability. It is suitable for grinding high-hardness materials, such as cemented carbide, ceramics, glass, etc. Diamond abrasive flap discs have high grinding precision, which can meet the requirements of high-precision processing. At the same time, it can improve processing efficiency and reduce processing costs.

Applications: Mainly used in high-end manufacturing industries such as cemented carbide tool processing, ceramic product processing, and optical glass processing.

Classification by Base Material

Paper-based Abrasive Flap Discs

Characteristics: The base body of paper-based abrasive flap discs is made of paper, which has the characteristics of soft texture and good elasticity. During the grinding process, this kind of flap disc can fit the surface of the workpiece well, and is suitable for grinding some workpieces with complex shapes and high surface requirements. Paper-based abrasive flap discs have a low cost and are easy to use, but their wear resistance is relatively poor and their service life is short.

Applications: Commonly used in industries such as furniture manufacturing, wood product processing, and handicraft processing.

Cloth-based Abrasive Flap Discs

Characteristics: The base body of cloth-based abrasive flap discs is made of cloth, which has high strength and wear resistance. Cloth-based abrasive flap discs can withstand greater grinding pressure and are suitable for rough grinding and semi-finish grinding processes. Compared with paper-based abrasive flap discs, cloth-based abrasive flap discs have a longer service life, but the price is relatively higher.

Applications: Widely used in metal processing, automotive repair, building decoration, and other fields.

Plastic-based Abrasive Flap Discs

Characteristics: The base body of plastic-based abrasive flap discs is made of plastic materials, which have the characteristics of light weight, corrosion resistance, and not easy to deform. This kind of flap disc is suitable for grinding some workpieces with high environmental requirements, such as food machinery, medical devices, etc. Plastic-based abrasive flap discs have a good grinding effect, which can ensure the cleanliness and hygiene of the workpiece surface.

Applications: Mainly used in industries such as food, medicine, and chemical engineering.

Classification by Shape

Round Abrasive Flap Discs

Characteristics: Round abrasive flap discs are the most common shape, with a simple structure and easy to use. The diameters of round abrasive flap discs vary, and appropriate specifications can be selected according to different grinding requirements. During the grinding process, round abrasive flap discs can evenly distribute the grinding force, making the grinding effect on the workpiece surface more consistent.

Applications: Widely used in various surface grinding and curved surface grinding processes.

Square Abrasive Flap Discs

Characteristics: The shape of square abrasive flap discs is relatively special, and it is suitable for grinding workpieces with right angles or edges. The corner part of the square abrasive flap disc can fit the edge of the workpiece better, improving the precision and effect of grinding. In addition, square abrasive flap discs can be assembled into grinding surfaces of different sizes by splicing to meet the grinding requirements of workpieces of different sizes.

Applications: Commonly used in the grinding of right angles and edges in industries such as mold manufacturing and machining.

Special-shaped Abrasive Flap Discs

Characteristics: Special-shaped abrasive flap discs are designed according to specific grinding requirements, and their shapes can be various irregular shapes such as ellipses, triangles, trapezoids, etc. Special-shaped abrasive flap discs can adapt to the grinding of workpieces with complex shapes, such as aero-engine blades, turbine blades, etc. These flap discs usually need to be customized according to the specific shape of the workpiece to ensure the accuracy and efficiency of grinding.

Applications: Mainly used in the grinding of complex-shaped parts in high-end equipment manufacturing industries such as aerospace and shipbuilding.